About us

Contact us

About us

Contact us

Find us

Find us

In addition to the above, there are several model engines, which run on compressed air.

Cameron Pump

A vertical two cylinder ram pump with central flywheel.

.

Fire Pump

A Horizontal, two cylinder steam ram pump.

Robey Engine and Pump.

Horizontal single cylinder engine driving a vertical ram pump.

.

Weir Boiler Feed Pump

A typical example of this widely used type of pump.

Click on a picture for more details

James Burton

Horizontal single cylinder engine from Newcastle University.

George Mills & Son

Duplex steam pump.

On static display only

Joseph Evans & Sons

Reciprocating steam pump having a typical banjo type crank.

Under restoration.

Marshall & Sons

Horizontal single cylinder engine driving a three throw ram pump.

Miscellaneous Steam Engines and Pumps

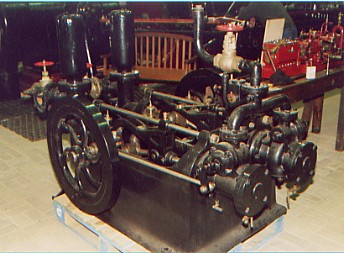

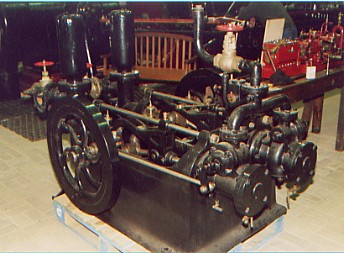

George Mills, Radcliffe, Manchester

A reciprocating steam pump, described as a duplex hydrant pump. The steam cylinders are 9ins diameter and pump cylinders 6ins diameter, sharing the same common piston rod. A disc crank provides the 12ins stroke. (History of the pump is unknown).

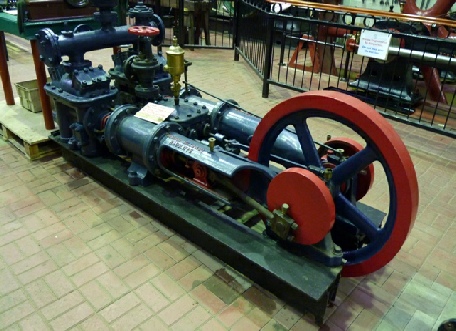

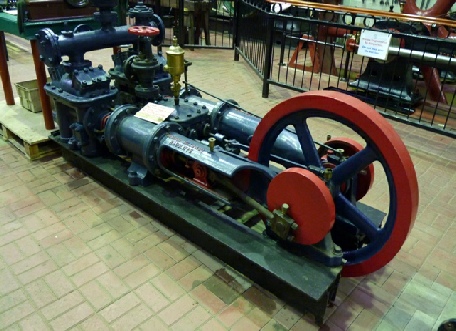

James Burton, Liverpool

A horizontal single cylinder, slide valve engine, 6ins bore by 9ins stroke.

54ins diameter flywheel. Speed controlled by a Pickering governor. This engine came from the University of Newcastle upon Tyne.

It was used in their Mechanical Engineering Dept where students would obtain indicator diagrams from the engine, at various speeds and steam pressures, in order to calculate the brake horse power.

Joseph Evans & Sons, Wolverhampton

A reciprocating steam pump, having a steam cylinder diameter of 6ins and pump cylinder diameter of 4 ins, sharing a common piston rod.

A Typical banjo type crank provides the 6ins stroke.

(History of the pump is unknown).

At present under restoration

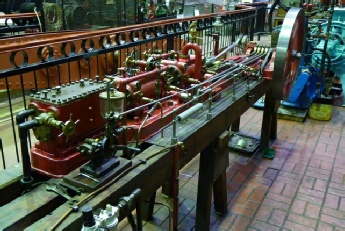

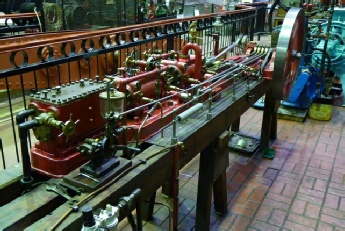

Marshall & Sons, Gainsborough No. 77243

A single cylinder horizontal engine, 9ins bore by 12ins stroke, 54ins diameter flywheel. Speed is controlled by a Pickering type governor.

(History of the engine is unknown).

The museum has adapted this engine to drive a three throw ram pump, which was originally driven by Agnes to provide water for her condenser/air pump.

The pump has 3 rams of 5ins diameter and a 10ins throw (stroke), driven by a 30ins diameter flat belt pulley through a 4:1 reduction gear train.

Fire Pump

A horizontal twin cylinder steam ram pump. Each steam cylinder, 4ins bore x 5ins. stroke, drives a 3.5ins diameter ram pump via a 'banjo' type crank (similar to Joseph Evans pumps). Each steam cylinder is controlled by a rotary valve driven by an eccentric on the crankshaft.

It looks as though it has been used as a fire water pump. No makers name or history is known.

John Cameron of Manchester.

A two cylinder steam pump, steam cylinder bores 5ins. Pump ram diameter 3.5 ins. with 6ins. stroke and 'banjo' type connecting rod etc.

The steam cylinders are located at the top and the pump rams at the bottom with a central flywheel 36ins. diameter.

The four supporting columns are hollow and connected to the pump delivery and act as air vessels, which even out the pump impulses.

No history of the pump is to hand at present. It is rumoured that 'it came from the basement of a steelworks somewhere in Sheffield'.

Watch restoration video on Youtube

John Thom , Patricroft, Manchester

Overhead crank ram pump. Was installedin the Tong Dying Company works at Middleton Way near Rochdale. It provided a source of water, which was used for bleaching and dying cotton cloth, brought in from the local mills.

In 1987 the pump and headgear was saved and subsequently refurbished by the apprentices of Rochdale Training Association.

It was then put on display in the Wheat Sheaf Centre, Rochdale in 1990. Dismantled and rebuilt in the museum in 1998.

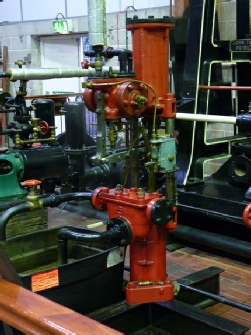

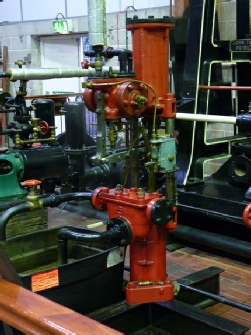

G & J Weir Ltd, Glasgow

A Vertical, direct acting, boiler feed pump. A very common type of pump, widely used in both marine and land based boiler rooms.

The reciprocating action is controlled by a clever ‘shuttle’ valve, which at the end of each stroke, shoots to one side or the other. Thus reversing the direction.

This particular example was in use at The Retreat Hospital, Heslington Road, York.

Completely dismantled and rebuilt in the museum and is now regularly steamed.

Model Tandem Compound Corliss Mill Engine.

On loan from Bradford Industrial Museum.

Although described as a model its size is quite big.

Cylinders: HP diameter 3"; LP diameter 4" and Stroke 8". Flywheel: 30ins. diameter.

Several model engines running on compressed air

About us

Contact us

About us

Contact us

Find us

Find us