| Museum News 2004 |

|

(Back to Archive News Page) |

|

May 2004. Reliant Paddle Tug, Side-Lever Engine - If you you remember the crankshaft came to us in two pieces, (see MUSEUM NEWS 2002) these have now been reunited. They were transported to Sam Ward's workshop in Kilamarsh, South Yorkshire where the oxy-acetylene burnt ends were machined square and a male and female spigot produced in the lathe. The two shafts were then forced together using a hydraulic press, rigged up in the lathe. At the joint a deep chamfer had been machined on both halves to produce a vee groove, which was filled by a continuous weld as the lathe slowly revolved. When finished the top of the weld was machined level to the original shaft diameter, which produced an almost invisible and extremely strong joint. The shaft is now back at the museum. |

|

Removing the paddle wheel hub and shaft from the lathe. Note the new machined left hand end. |

|

The repaired paddle wheel hub and crankshaft back at the museum. |

| (Photos - Paul Bond) |

|

Only one half of the slip eccentric has survived. A fabricated replacement for the missing half has been made 'in house' and is, at this moment, being machined in the museum workshop. It is intended to have the paddle wheel, and its paddle feathering gear, operating alongside the engine. A large fabricated structure is now in place (to substitute the side of the tug), which will support the paddle shaft bearing. |

|

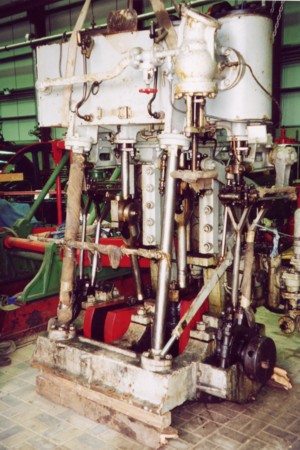

Yarwood Vertical Compound Marine Engine No. 193 (Out of the dredger 'SEIONT II).

|

| The Yarwood compound marine engine just as it was after unloading. |

|

|

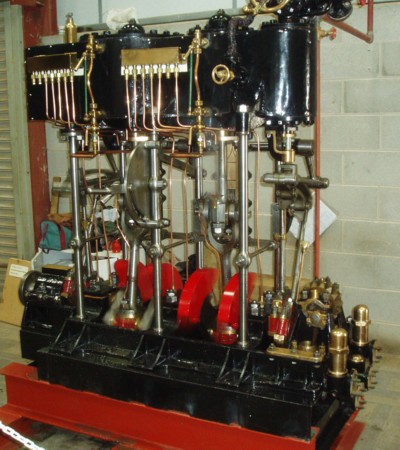

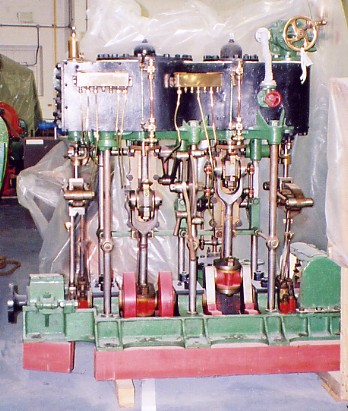

Samuel White Vertical Marine Compound Engine No.1239

We also took the opportunity to check the valve port openings and the amount of lead on both the HP and LP steam cylinders ie. the amount the steam port is open when the piston is on top and bottom dead centre. On marine engines it is common practice to have more lead on bottom dead centre that on top dead centre. This is to allow for the weight of conrods and pistons etc. to be lifted against gravity.

Early in February the engine was again tried on steam. Thankfully this time it started straight away and ran quite well - slightly smoother in 'forward' than in 'astern'.

|

|

Samuel White vertical compound marine engine after restoration. |

|

Samuel White vertical compound marine engine before work started on it. |

|

Fleming & Ferguson Marine Engine. This engine has always run a little bit uneven, particularly at slow revs. It was recently decided to replace the existing flywheel with one of a larger mass and a balance weight to counter the 'out of balance forces' of the engine.

|

|

The modified flywheel being lowered into place. The balancing weights can be seen quite clearly. |

|

June 2004. Monday 21st June saw the arrival of another engine at the museum - A horizontal, single cylinder, slide valve engine, and four bar cross-head guides.

|

|

Stripped down to the cylinder and bed castings. |

|

The slide valve with cover removed. |

| The finished engine. |

|

|

|

|

Reliant Paddle Tug, Side-Lever Engine

The existing paddle wheel arms and rims were separated from the hub some time before they arrived at the museum. Their relative positions to each other were not recorded, therefore one or two trial assemblies of all parts will have to be made before an acceptable fit can be arrived at. After that a new set of arms (mirror image of the existing arms) will have to fabricated and individually fitted to complete the wheel framework before the paddles can be fitted. |

|

Trial fitting of parts of the paddle wheel frame to the hub. |

|

Yarwood Vertical Compound Marine Engine No. 193 Progress Report: After a bit of research and head scratching it was found, that at some time prior to the engine arriving at the museum, the eccentic rods had been crossed over. They have now been fitted to their correct eccentrics.

|

|

The Yarwood Vertical Compound Engine under restoration. |